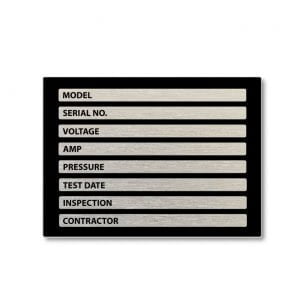

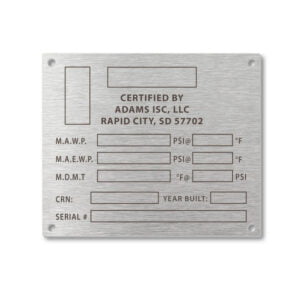

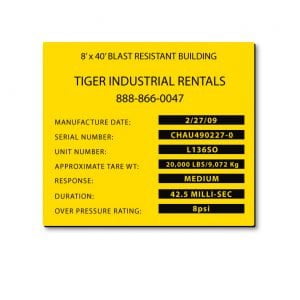

Data Plates, also referred to as equipment name plates, load plates or machine data plates, are an effective way to display machinery and equipment information. Depending on your equipment data plate standard, this can include manufacturer, model, serial number and other vital data. In addition, the plates display pertinent safety information to help avoid preventable accidents and injury caused by equipment misuse.

Data plates come in a variety of materials, including Stainless Steel, Aluminum, and Plastic and usually include easily stamped or scribe-able boxes for in-field marking and custom identification done by the end-user.

Equipment Data Plates Requirements

Whether it’s an OSHA requirement, a MIL-Spec contract, or a simple means of displaying safety information, Inland Products can produce high quality data plates for any requirement. Be sure to know your required equipment name plate standard before deciding what you need on your data plates. There tends to be limited space on these plates, so it’s important to know what information to include. Here’s some information to help you figure out what to put on your data plate and why it’s important:

What to Put on a Data Plate ~ OSHA

It’s essential to have all of the information about machinery to reduce risk and keep a safe environment. However, remember that training is key. Though your load plates display the vital information, without training, drivers won’t be able to decipher the meaning of each metric. Keep this in mind. Add it to the safety training for new employees who work with heavy equipment. Only trained personnel should operate the equipment—otherwise, it’s a safety hazard.

With that said, here’s information to include on your equipment data plates:

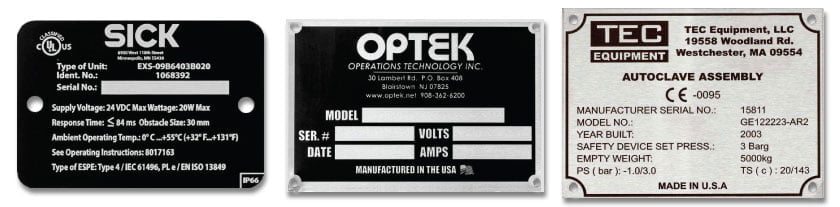

Model and Serial Numbers

The model number is vital to include on data plates for repair, technical issues, and capacity. Further, it comes in handy when you need to look up parts on the manufacturer’s website. The serial number is required on all heavy equipment—per OSHA regulation 29 CFR 1910.178(a)(3) and is likely the most crucial number for technical communication.

Fuel Type

Another detail that the equipment operator must know is what type of fuel the equipment uses. Consequently, type indicates if the machinery uses diesel fuel (DS), gas (G), electricity (E), liquefied petroleum gas (LPS), or compressed natural gas (CNG).

OSHA has specific regulations for the type of environment, too. Regulation 1910.178(c)(2)(iii) states that you can only use an EX powered forklift that’s specifically assembled for atmospheres containing flammable vapors in a warehouse where hazardous materials such as natural gas, vinyl chloride, or other ignitable mixtures exist.

Weight and Capacity

The weight and capacity must be included on the load plates as well. While weight and capacity are two different things, they are interrelated. For example, a forklift’s capacity measures how much weight a forklift can lift, which is dependent upon its overall weight distribution.

Replacing a Data Plate

If a piece of equipment gets any modifications, or it has an attachment, the equipment capacity plate must be updated to reflect the new capacity. Also, if a data plate falls off, or you can’t read it, you must replace it. Whether you need one or thousands, we’ve got you covered at Inland Products.

FCC Regulations

The FCC has two equipment authorization procedures. First, there’s the Supplier’s Declaration of Conformity, and secondly, the certification for the RF device, which specifies the equipment authorization. What needs to be on the data plate depends on the type of equipment.

There’s a unique identifier that positively associates the device with the compliance test reports, which may include the number, model number, or serial number utilizing the responsible party’s internal manufacturing process. Additionally, you’re required to include compliance information such as trade name and model number.

Also, devices may be authorized to use the FCC logo to indicate compliance with the FCC rules. For certification, the FCC ID must always be accessible when using the product. What this means is that the placement of the FCC ID must be a data plate on the surface of the product and permanently affixed.

Not only that, but the FCC requires some RF devices to have information, including their FCC ID, warning statements, or other information either on the device or its packaging.

Other Industries

Other than heavy equipment, construction, and telecommunications, there are a variety of industries, including aerospace companies that utilize data plates. Make sure you understand the regulations for your business.

The bottom line? There are critical elements to include on the equipment data plate, depending on the industry.

Data Plate Ideas

Inland Products is a manufacturing company with full tool room capabilities. We have the tool and die makers to handle custom projects that our customers can’t do in-house. Whether you’re a large manufacturer who needs thousands of load plates or a small company who only needs a few, we’ve got you covered at Inland Products.

We also sell our blank items to other companies who personalize and resell them to their customer base. You can count on quality and timeliness as we’ve been manufacturing identification products for over 25 years.

Not only that, but all of our options come in plastic, anodized aluminum or stainless steel in various sizes to fit your needs.

Plastic

A plastic data plate may be the best option depending on the product—they’re bright and durable—perfect for labeling fans, pumps, air handling units, and more. Plastic data plates also tend to be a little less expensive.

Plus, the various color options provide high contrast for easy visibility between the white or black letter color and the background color.

Anodized Aluminum

If you’re seeking data plates with lots of versatility, aluminum is an excellent choice. It’s lightweight and corrosion-resistant, which makes it perfect for the aerospace industry. Plus, you can choose the color of your Custom Aluminum Data Plates. We offer anodized aluminum in eleven colors.

One advantage of anodized aluminum is the high contrast between the surface color and the engraving. Some anodized aluminum tags are rotary engraved, so the engraving cutter cuts through the anodized layer and into the core aluminum. The result is that the engraving is a bright silver color, contrasting the surface of the data plate.

Alternatively, aluminum tags can be laser etched, in which the laser simply burns through the surface color but not down to the core aluminum. In this case, the engraving ends up white because the oxide layer shows through in the etched areas.

Stainless Steel

By far the most durable metal tags, stainless steel is the hardest metal we use for data plates. It’s twice as hard as brass and up to four times as hard as aluminum. It also has a higher resistance to abrasion, damage, and extreme weather conditions up to 2500 degrees Fahrenheit.

What’s more—the top grades resist corrosion from strong acids or alkaline materials.

Inland Products offers two different grades, using a different mixture of alloys to give each grade differing properties and capabilities. Type 430 is the least expensive and works for most applications. It won’t rust in most applications. It’s also durable and heat resistant. However, it does lack the high corrosion resistance of the higher grades.

The next grade is Type 304. It’s a bit more expensive, because it’s a harder material and slower process. However, it offers better corrosion-resistance than Type 430.

Make Sure You’re Meeting Industry Standards

Now that you know what to put on a data plate, take the time to ensure you cover your equipment with all the information you need to comply with your industry’s regulations. Whether you’re a large manufacturer producing heavy equipment, a telecommunications agency, or you’re in aerospace or construction, you need a data plate for your products.

What’s more, you may own a small engraving shop, sign, and graphics company, or printing business that doesn’t have our manufacturing capabilities or expertise to produce the blank items. We can supply preprinted blanks too.

We’re Here To Help!

Inland Products has an experienced, knowledgeable, and helpful sales staff waiting to answer any questions you may have. We are here to help you make the best choices for your metal plates!

Please call us at 1-800-481-5500 or email sales@inlandproducts.com